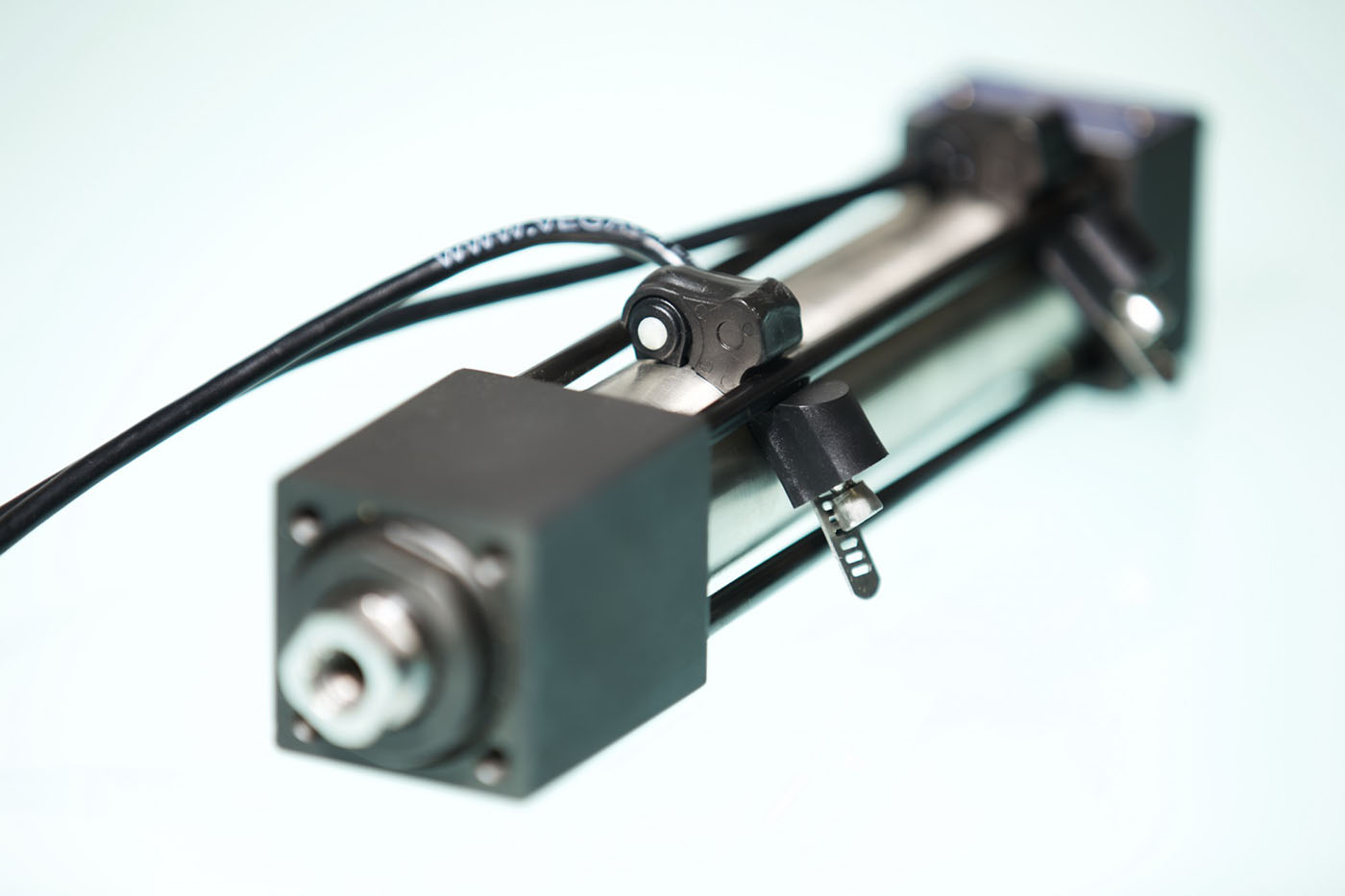

A cylinder stroke is the distance covered by the rod and the piston between full-in and full-out positions. It can also be defined as the difference between maximum extended length and minimum extended length.

In Vega cylinders, stroke is part of the cylinder code, and it is reported on the nameplate. In cylinder catalogs, stroke values are reported along with ‘block’ length and ‘protruded-rod’ length. By summing up the last two values, the total length in retracted position is gained; by summing up all three values, the maximum length of the cylinder, with a fully extended rod, is gained. On our website, it is also possible to download cylinder drawings in a full-in or full-out position, according to one’s wishes.

But how can the right stroke be chosen? Let’s review some of the more common strokes and their applications.

Short Strokes

We consider short strokes all strokes below the ‘nominal’ value of 100 mm. This is the case of most block cylinders. When strokes are smaller than 100 mm, all problems that might arise are negligible. There will be no need for buckling, and wearing or leaking caused by side forces will rarely happen. Also, rod ‘shortening’ due to compression will be negligible as well. Speed and end-stroke shocks are low and few, and oil compression and piston ‘bouncing’ will be at their minimum if using a check valve. Only mold design errors can cause cylinder problems to arise in such cases.

As already discussed in another article of this blog, hydraulic cylinders may be highly stressed when withstanding injection force coming from molded parts. Generally speaking, this force is exactly along the cylinder axis, and during this phase the rod will be highly compressed. Therefore, it’s important to take into consideration all the possible variables in order to avoid defects in molded parts, such as burrs or ‘flashes’.

For example, the V260CF series has been designed to face this kind of issues and to pre-load rods in order to avoid any sort of defects. At page F5 of the catalog, the minimum compression value to be followed is reported. Applying these values and using the proper pre-old flange, burrs and “flashes” can be easily avoided. For further information about pre-loads and V260 CF cylinders, watch the following video.

Long Strokes

Long strokes are strokes longer than 100 mm, and they involve other kinds of challenges, especially within a mold. Two of these challenges are the issue of speed and the issue of kinetic energy caused by large masses in movement, but they can be solved with a good cushioning system. However, there are still other issues related to some habits of many mold designers. For example, some of our customers have mechanical parts—usually brackets or wedges—connected to the cylinder rod. This connection is often very rigid, loading the cylinder and giving it a bending motion. If the rod is fully in, then there are low forces contrasting this motion, and therefore the flexural deflection of the rod is quite small. On the other hand, when the rod is fully out, the rod is subject to very high forces contrasting the bending motion, and the deflection of the rod might be quite severe. All of this might cause oil leaks, breakages or other problems.

In order to solve these problems, there are two solutions that are usually suggested:

- Use a floating joint between the rod-end and the part connected to it. When properly installed to the matching part, floating joints allow only axial forces to be transferred, cutting off all bending effects on the rod.

- Use a spacer. This is the solution adopted by Vega in case of extra-long strokes, as described below.

Extra-Long Strokes

Sometimes customers ask for special strokes, especially for V215 CR tie-rod cylinders. The length of these strokes might be way longer than 100 mm, and therefore are extra-long strokes. If it exceeds the maximum recommended one, Vega will likely advise to use an additional spacer. It is installed on the rod, and against the piston. When the rod is full out, it leans on the head inner face, so keeping the piston away from it. In this way the rod can be guided much better and is stiffer. Of course, the rod, cylinder tube, tie rods and consequently overall length, will be increased by the same value as the spacer length. Doing so, the stroke will remain the same as required by the customer.

Do you want to know how to apply Pre-Load on Vega V260CF Locking Cylinders? Watch this video, and don’t forget to subscribe to our YouTube channel!