As told by Dr. Bruno Barne.

My experience and the using of Hydraulic cylinders started at the same moment, in 1990.

When I arrived at Sommer Allibert Industrie (which became Faurecia Interior Systems in 2000), standardization of molds was in its infancy. Quickly, it was identified that the coordination of the ejection between the mold and the injection machine was a task which required a lot of time, thus the reason for making the ejection independent of the injection machine by using hydraulic cylinders. That decision helped develop HP system as a supplier to the injection sector.

From this date and for many years, HP system was the only supplier for hydraulic cylinders to Faurecia Interior Systems.

In 2011, Faurecia Interior Systems decided to open the panel of suppliers. Firstly they added PARKER and AHP MERKLE but they also looked for another brand.

Previously, when I started to work with VEGA in 2007, I presented the company, its products and the philosophy to some Faurecia Interior Systems people and in June of 2011 we received a request to situate our price level.

Following that, we engaged in some technical discussions, and in February of 2012, we delivered 4 cylinders with modified fixing points. Effectively to evaluate our cylinders, Faurecia Interior Systems decided to do a real test mounting them on a mold already in production in the Saint-Michel plant. The daily volume of the mold was more than 1500 cycles per day. The first concern was to check if the mold worked the same as it did with the HP System cylinders, which means with at least the same cycle time and also with equilibrated ejection plate movement.

After several month of production, Faurecia Interior Systems has confirmed that the mold was working properly and we suggested to do an inspection after 6 months of production. In July 2012, in the presence of Faurecia Interior Systems’s maintenance people, our technician dismounted all the cylinders. All the components were in perfect condition and the cylinders were mounted again on the mold. After one year of production (300.000 cycles), the conclusions are the same (To see answers from the plant to some question:

“Volume de production à ce jour avec ces vérins ( 1500v/j soit 300 000 moulées environs )

– Avez vous eu un quelconque problème pendant la production cette année ? Si oui de quel ordre ?Non,aucun soucis et aucunes fuite

– Maintenance : avez vous fait des actions de maintenance spécifiques depuis l’analyse du mois de Juin ? Et le cas échéant quels sont vos constats ? Aucunes actions en maintenance“

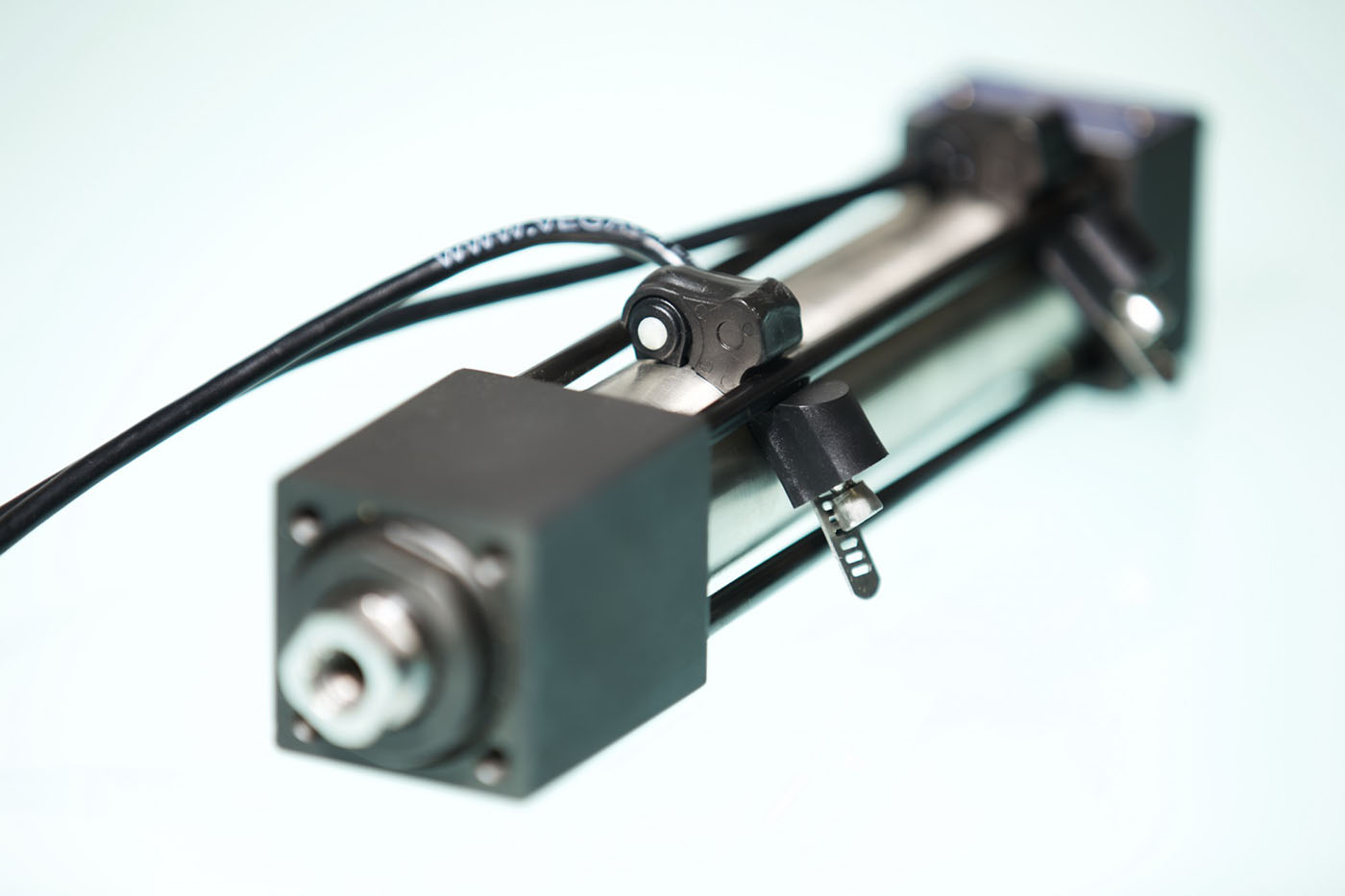

In parallel, I used the experience of my years working at Faurecia Interior Systems, my knowledge of the specifications, and the expectations of maintenance people to propose the best solution, taking into account of course the cost, but mainly the maintenance aspect and to give the plants the best solution. This led me to propose the Vega V450 cylinders with standard strokes.

Also, to identify the cylinders for Faurecia Interior Systems (specification details different of our standard) and for better tracking of our products, we created a special reference.

After more than one year and several meetings, we finally reached the first target in 2014 with our nomination into the Faurecia Interior Systems mold specification.

However, today many situations have changed. The decision is in the hands of the mold maker. Effectively, in the past, either there was only one choice or the plant forced the use of one specific brand. Now it is different, the mold maker can choose the best supplier for him from a list of brands according to his own criterions. The plant can still suggest, but not obligate, and in this case has to assume its choice…….

Now, we have a new target. After being in Faurecia Interior Systems (FIS) specification, we are aiming to reach the same target with Faurecia Exterior Systems (FES). I hope that 2016 will bring us good news!