As many of you already know, our online cylinder configurator has been available on our official website for many years. But as our official website kept evolving—adding new features and innovations as time passed by—our configurator couldn’t but keep the pace and get updated as well. But why was it necessary to update our configurator? What are its new features? And how did Vega manage to do it?

In order to answer these questions, we decided to interview Daniele Draganti, project manager and director of Keletes, the company that designed the new configurator.

Good morning! First of all, what is Keletes, and how has it been helping Vega these last few years?

Keletes makes innovation its greatest strength. Born from a little group of industry experts operating since 2007, Keletes is based in Busto Arsizio, near Milan, technological core of Italy. Our product presentation platform was born from the need of Vega to have a complete system that was also customizable, light and quickly responsive. We use the most advanced technologies in the IT sector — cloud computing, quick software development, multi-platform API — to guarantee innovative, reliable and safe end products.

The Vega website is well-known for its configurator—why is it so important?

Nowadays, many molders do not use CAD systems alone in order to design their products, but they are accustomed to working in real time in 3D. Seeing that designing a mold with these systems, even though practical, really takes a lot of effort, engineers rely on libraries of predefined components, so as to avoid “reinventing the wheel” every time they need a standard component. That same holds true even for more complex parts, such as cylinders.

A configurator that allows to set the cylinder according to one’s own requirements, sending back a 3D file ready to be used by all the most common CAD systems, gets rid of efforts needed to manually dimension the cylinder from paper catalogs or 2D drawings.

Vega was the first company to provide an online configurator for its products; our colleagues—almost 20 years ago—worked in close collaboration with developers of one of the most important CAD systems, awing several computer and mold injection experts.

Why was a new configurator necessary?

During the last 10 years, Internet technologies changed drastically. Whereas a few years ago a technology like the one used by our configurator required specific extensions and programming languages to be installed, nowadays such features are implemented directly in every user’s browser. Consequently our solution—highly innovative a few years ago—became obsolete and almost unusable by today’s standards.

Moreover, these new technologies open up the way for new features that not long ago would have been unimaginable and impossibile to add to our old configurator.

Of course Internet’s ongoing evolution greatly changed the technologies we use today. What issues the old configurator had?

To begin with, the old configurator—just as the old website in its entirety–was limited to one browser only, no more supported by new operative systems. This led to many “strange” errors, and things were bound to get ever worse as the features used by our developers were taken away from browsers and replaced with newer versions.

Another reason that led us to redesign our whole system is that the CAD file generation on our servers was based on a third-party commercial program. As such, it was unthinkable to widely distribute it—for example by USB keys—and it limited the control we had on implementing some features.

What did you to do to solve these issues? What new features and advantages does the new system offer?

The new configurator had to be remade from the beginning, and nothing ‘old’ has been used. This choice had to be pondered very carefully, since it clearly involved risks: the old configurator had been tested for over 2 decades, and it was fairly stable thanks to continuous fixes, whereas a new technology at first is always somewhat flawed, and it gets corrected as it’s being used. So why did we take this road? Because its benefits in time are by far greater and priceless.

Let’s talk about the technology used. Even though most of our users will log into the configurator via our website, the programming method that’s used is actually much more similar to developing an application than a mere website. Once the base parameters for the cylinder have been set, the interface can access to those data and provide the user all the information they need in real time.

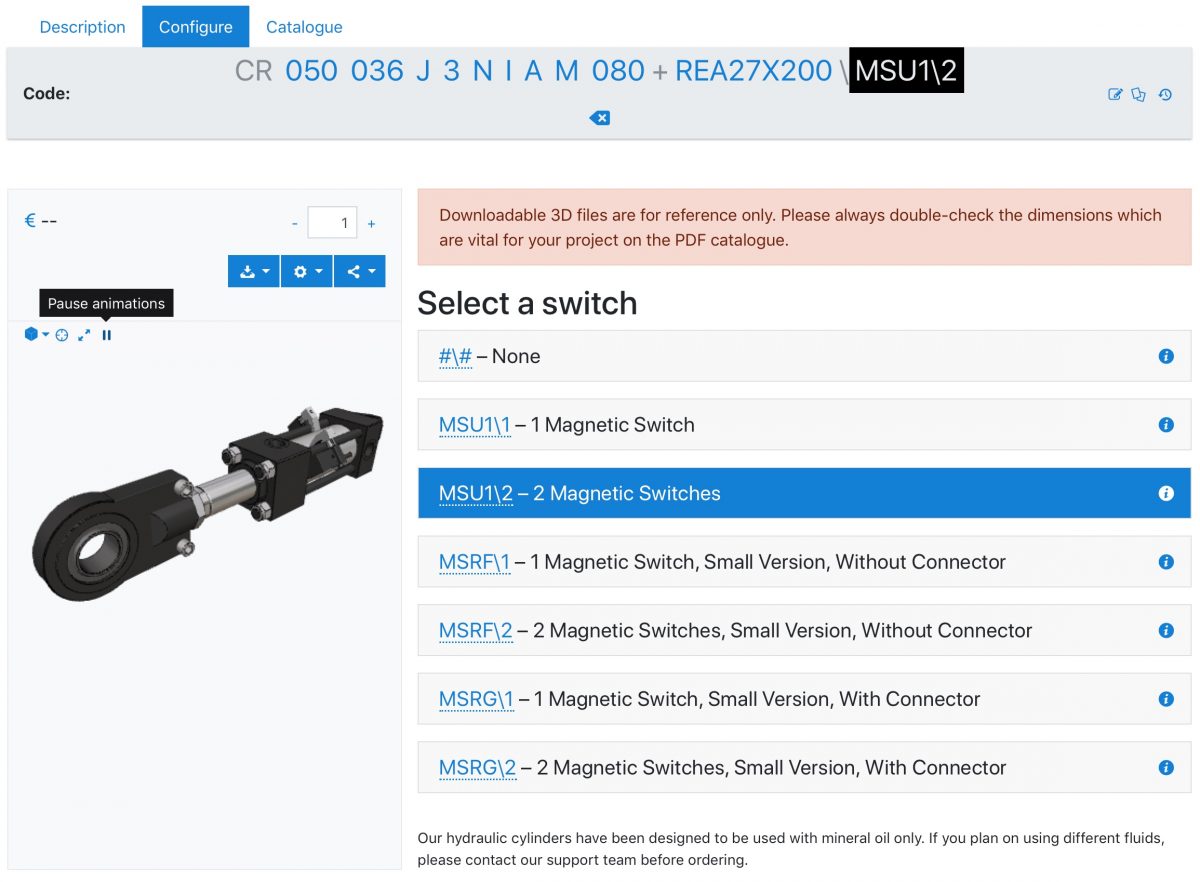

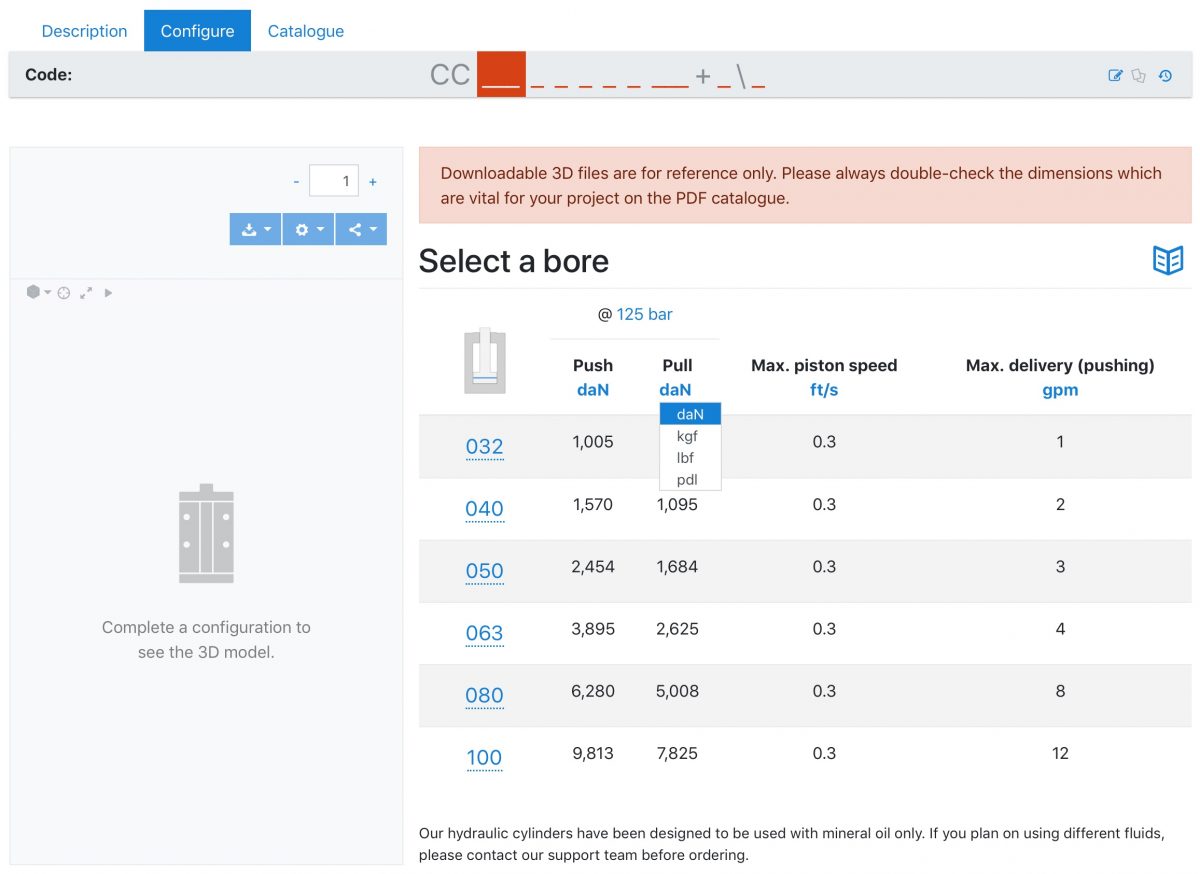

For example, you’ll see that if some measure units in the reference tables do not satisfy you, you can select a different unit, and all the tables will be automatically converted. The software will check in real time wether the commercial code inserted is correct, and if something’s wrong it will automatically get you to the page where the error has been found, showing all the possible solutions on top.

3D models are generated through an Open Source CAD software; this means that it is a commercially unlicensed software with an open code, that can be changed as we please. For this reason, we can constantly improve it and provide models that are more and more accurate—actually, generation time for many of our cylinders are already pretty quick. Most of our drawings have already been converted to the new configurator in very short time in order to offer our customers a complete service, but we’ll keep improving its details and quality as time goes on.

Especially thanks to the Open Source CAD, we can finally provide an offline configurator to our agents and customers who cannot surf the web on their computers because of their company policies.

Generally speaking, having full control over all the technologies used for this new configurator opens the way for new features and solutions that were impossible to implant with the older version.

Now you have definitely stirred our curiosity! What do you have in mind for the future?

The most exciting feature is the complete parameterization of the cylinder data. This software is capable of recognizing every key-feature—such as maximum pressure, force of traction and thrust, speed and temperature—for every configuration of each and every cylinder.

Potentially, a designer may choose to insert their required parameters and a receive a list of all cylinders suitable for their needs, or insert a commercial code and see what products are compatible. Going even further, it may be possible to create a simulator with a list of all the most common solutions in the mold-injection field—such as pin moving, plates, etc.—and give our users the opportunity to test different cylinders under particular conditions, and see how each cylinder will react, just as if it were the real thing.

And this time we’ll keep our code always updated, so we have no doubts that we’ll be able to surprise you with everything you are going to see in the near future on our website!