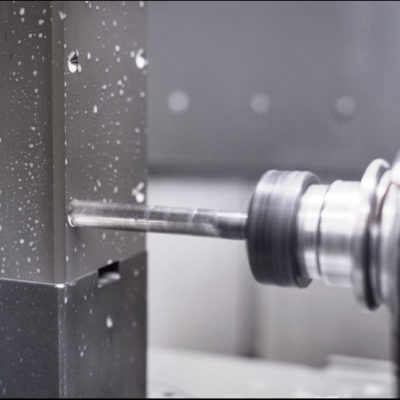

In July 2015, one of our customers sent us the following picture, asking for a new locking cylinder to replace the older one. As we enquired on what had happened—and why they thought a new cylinder was needed—we found out that oil was leaking from the rod.

Actually, we were not much surprised, since the shape of the front pre-load flange had been completely modified from the original one. Many fixing holes were removed, and so the cylinder had less resistant sections to withstand locking forces.

On our official catalog and on our website, the original pre-load flange and the minimum number of screws needed to fix it can be seen. If not fixed properly, the rod will be working in a bent position, causing stress to be placed on its seals and causing oil to leak.

We strongly recommend considering all the information on our catalog when designing injection molds, and please refrain from customizing Vega cylinder components.