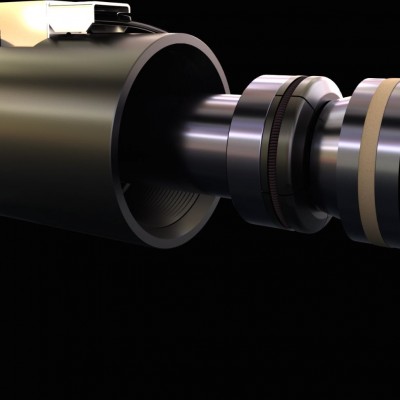

With the constant growth of our company and a significant increase of the request from our customers, we decided to expand our production line of hydraulic cylinders for molds.

We bought a brand new DOOSAN NHP5000 and a DOOSAN PUMA 2600Y.

These two machines are already working and supporting the production of VEGA hydraulic cylinders factory.

Thank You OVERMACH SpA for these great products!

DOOSAN NHP5000

“Unbeatable linear roller guide horizontal machining centers in a compact layout. Built for massive metal removal, these machines can single-handedly change your business.”

DOOSAN PUMA2600Y

“Thanks to its integrated Y-axis and integral drive spindles, the PUMA 2100/2600(II) lets you handle the part from beginning to end on one machine. Put simply, it’s a productivity godsend.”

What does it mean to our customers?

We know from experience, that mold makers, while choosing hydraulic cylinders for their projects are searching not only for a company that can provide a fast delivery and pre/post sale support.

One of the most important things is high quality, durability in time and a remarkable reliability of hydraulic cylinders.

With our new machinery we are able to improve our job and do even better than before.

VEGA General Director comment – Alessandro Formenti

What has changed in the production of cylinders in Vega?

Over the last 5 years we started a journey with a fix goal, that is “Industry 4.0”.

In order to achieve that goal we decided to change our mindset and approach our production with new concept.

All our machines, our stock, assembly, testing and packing units had to be replaced or adapted to be integrated with a software called MES. MES is a software that comunicate through our managing software and all hardware devices.

We can reschedule a work order from production and automatically the final customer is updated. We can control all CNC machines from a tablet and we can monitor and update info to our working staff. Because of this different approach to our production we updated our old machines and we open our mind to new tools, clamping accessories, and programming techniques.

So again, what does it mean for our customers?

Precise costing, faster delivery and containment of prices increases. As we have all experienced the price of steel, aluminum, energy and so on have taken a dramatic upward turn.

In Vega we are working to contain cylinder prices’ increase by analyzing our costs through the use of MES software and speeding up machine operations and using new mind-blowing drilling and milling tools. Having done that part, our staff can focus of other aspects of our process to save further production costs. Planning our purchases and anticipate the market is key to succeed in cutting costs but keeping our quality unchanged.

Quality for us means to keep our product and service quality steady but upgrading our systems to reduce costs and be more productive.