When it comes to hydraulic cylinders, test-rooms go a long way. As already mentioned, not only they allow to see both pros and cons of different cylinders, but they also give the chance to fix eventual problems and come up with amazing innovations. In order to do all these things, Vega set up a new test-room over the last few months. But what is it like? What are its benefits? See for yourself!

2008 POWER UNIT

This hydraulic power unit, along with its test-bench, has been used since 2008 to test the durability of most of our cylinders by causing the rod to go back and forth many thousands of times. Usually, cylinder tests involve one million of cycles, that is, one million strokes forward and one million strokes backward. The maximum working pressure is around 300 bars. An electric panel allows to invert electrovalves either by using the cylinder sensors or—if the cylinder has no sensors—by setting a timer.

This hydraulic power unit, along with its test-bench, has been used since 2008 to test the durability of most of our cylinders by causing the rod to go back and forth many thousands of times. Usually, cylinder tests involve one million of cycles, that is, one million strokes forward and one million strokes backward. The maximum working pressure is around 300 bars. An electric panel allows to invert electrovalves either by using the cylinder sensors or—if the cylinder has no sensors—by setting a timer.

2019 POWER UNIT

The greatest pride of our test room is this new hydraulic power unit. With 500 bars of pressure and 70 liters per minute, we can test our cylinders as never before, simulating even the most extreme conditions. Safety equipments in case of fire or other hazards have been implemented. Remote controlling and monitoring is now possible thanks to the brand-new control panel. Moreover, a chiller has been added, in order to cool down the fluid being used and to simulate several different temperature scenarios.

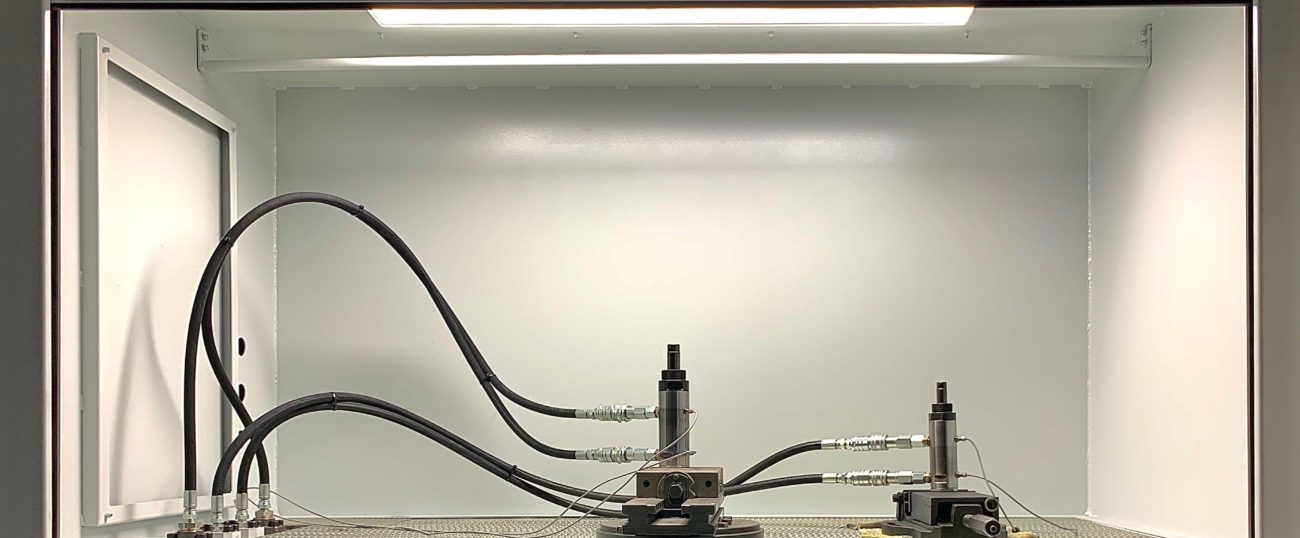

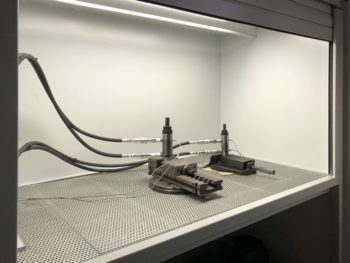

2019 TEST-BENCH

As pictured, the test-bench of the brand-new power unit allows to test more cylinders at once. These tests can involve different fluids, especially hydraulic oil and water-glycol mixtures. Thanks to the safety equipments and remote controlling systems mentioned above, it is now possible to perform these tests 24/7 in most complete safety!