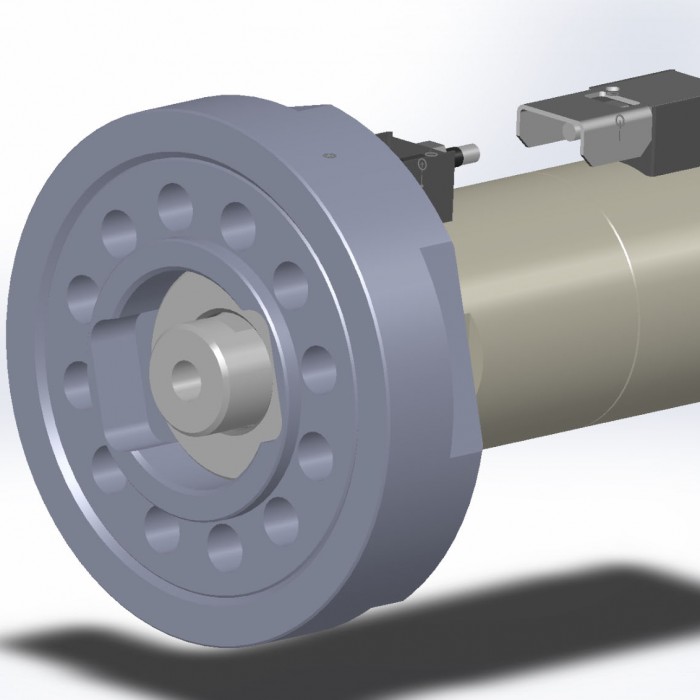

Some time ago, one of our customers found himself exactly in this situation—the pin needed for actuating his cylinder switches got broken. It’s not hard to figure all the problems this breakage may have caused! How did it happen?

Analysis Results:

As a careful examination showed, there are two possible reasons explaining why the pin broke down:

- Wrong switch maintenance/replacement procedure. A wrong mounting/dismounting procedure of the front switch group (toward the ending of the rod) or rear switch group (opposite side) may constrain the pin. This would cause the pin to break during the very first actuations of the cylinder, as the following picture shows:

- Excessively high working speed. An excessively high working speed (determined by oil flow) along with the moving mass may greatly increase the end-stroke impact of the rod/piston, thus causing the pin to break.

Possibile solutions:

- If the pin broke down because of wrong maintenance procedures, there is only one possibile solution: proper maintenance. So, when replacing sensors, pins and/or O-rings, we suggest placing the rod/piston opposite to the sensor group on which the maintenance procedure is to be performed, as shown in the following pictures:

- In case the breakage is caused by excessively high working speed, we suggest reducing oil flow and/or using check valves (see catalog of Vega products)

As always, knowing your cylinder—its features and its limits—will help you avoid misusing it. But that’s not enough—a regular, quick, and well-performed maintenance can be the key in prolonging the lifespan of your cylinders, as the following article shows: https://www.icvega.com/support/maintenance-importance-quick-accurate