Three years ago, Vega started commercializing a new series of tie-rod cylinders, named V210 CR. These new cylinders can boast higher specifics compared to our older tie-rod cylinders. Moreover, they can also boast some new features, such as a whole new cushioning system. All these things make this series one of the best we have ever designed!

In this article, we will discuss the main pros of the brand-new cushioning system, highlighting what it’s so special about it.

The Usefulness of Cushioning

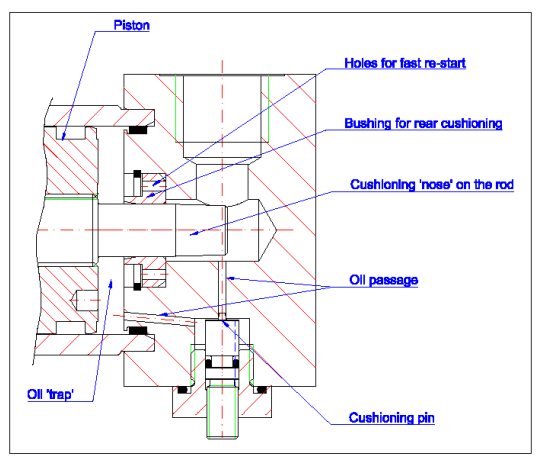

Cushioning systems are well-known and widely used in general hydraulic applications, but mold makers are less likely to be using them so much. However, they can be quite useful, especially when piston speed is higher than 0.1 m/s and the mass connected to the cylinder is not that negligible. In fact, cushioning allows kinetic energy to be absorbed just by trapping oil into a virtually closed room at the end of the stroke, and by letting it flow out through a very narrow passage. All of this causes oil speed to increase, generating a pressure drop which, multiplied by the length of cushioning, will match the energy to be absorbed.

Vega design optimizations while producing the V210 CR tie-rod series allowed for a huge improvement of the following features:

- constant absorption force along cushioning stroke;

- easy cushioning effect adjustment;

safety against cushioning pin over-opening; and - fast opposite direction re-start.

The following schematics show the aforementioned cushioning principles at the rear side of a cylinder as an example.

Yes, a good cushioning system can avoid lots of problems. Do you want to know more about cushioning and Vega cylinders? Don’t forget to subscribe to our YouTube channel!